In the electrifying world of electric vehicles (EVs), the choice of battery technology plays a pivotal role in shaping the future of transportation. Prismatic battery has emerged as a key enabler for the EV industry, offering a combination of performance, reliability, and versatility that is driving the transition towards sustainable mobility. Let’s delve into why prismatic batteries are indispensable for the EV industry and introduce SZJ Automation‘s Prismatic Lithium Battery Cell Assembly Line, designed to empower EV battery manufacturers with unparalleled efficiency and innovation.

The Rise of Prismatic Lithium Batteries in the EV Industry

Driving Efficiency and Performance:

Prismatic batteries are revolutionizing the EV industry by offering several key advantages:

Space Optimization The flat, rectangular shape of prismatic batteries allows for efficient use of space within the vehicle, maximizing storage capacity without sacrificing interior room or design aesthetics.

Enhanced Energy Density Prismatic batteries boast impressive energy density, providing EVs with longer driving ranges and improved performance, making them ideal for long-distance travel and everyday commuting.

Customization and Flexibility Manufacturers can customize the size and shape of prismatic batteries to fit different vehicle platforms and design requirements, offering greater flexibility and adaptability for EV models of varying sizes and configurations.

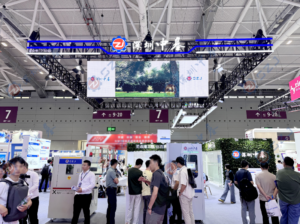

Introducing SZJ Automation’s Prismatic Lithium Battery Cell Assembly Line

At SZJ Automation, we understand the critical role that efficient and reliable battery manufacturing plays in the success of the EV industry. That’s why we’re proud to introduce our state-of-the-art Prismatic Lithium Battery Cell Assembly Line, designed to meet the evolving needs of EV battery manufacturers:

Key Features:

Steady Production Efficiency (6-24 PPM) Our assembly line ensures steady production efficiency, with the capability to achieve rates ranging from 6 to 24 prismatic batteries per minute. This impressive throughput enables manufacturers to meet demanding production targets with ease and efficiency.

Continuous Laser Welding Technology Leveraging our self-developed continuous laser welding technology on the top cover edge, our assembly line increases efficiency by more than 3-5 times compared to conventional segmental welding methods. This innovation enhances productivity while maintaining superior welding quality and reliability.

Customized Solutions We offer tailored solutions to meet the specific requirements of EV battery manufacturers, whether it’s adjusting production capacity, accommodating different battery sizes, or incorporating specialized features. Our team works closely with clients to deliver solutions that align with their unique needs and objectives.

Conclusion

In conclusion, prismatic batteries are at the forefront of innovation in the EV industry, offering unparalleled efficiency, performance, and versatility. With SZJ Automation’s Prismatic Lithium Battery Cell Assembly Line, EV battery manufacturers can capitalize on these advantages and drive the transition towards sustainable and electrified transportation. Experience the future of EV battery manufacturing with SZJ Automation and unlock new possibilities for efficiency, reliability, and innovation.