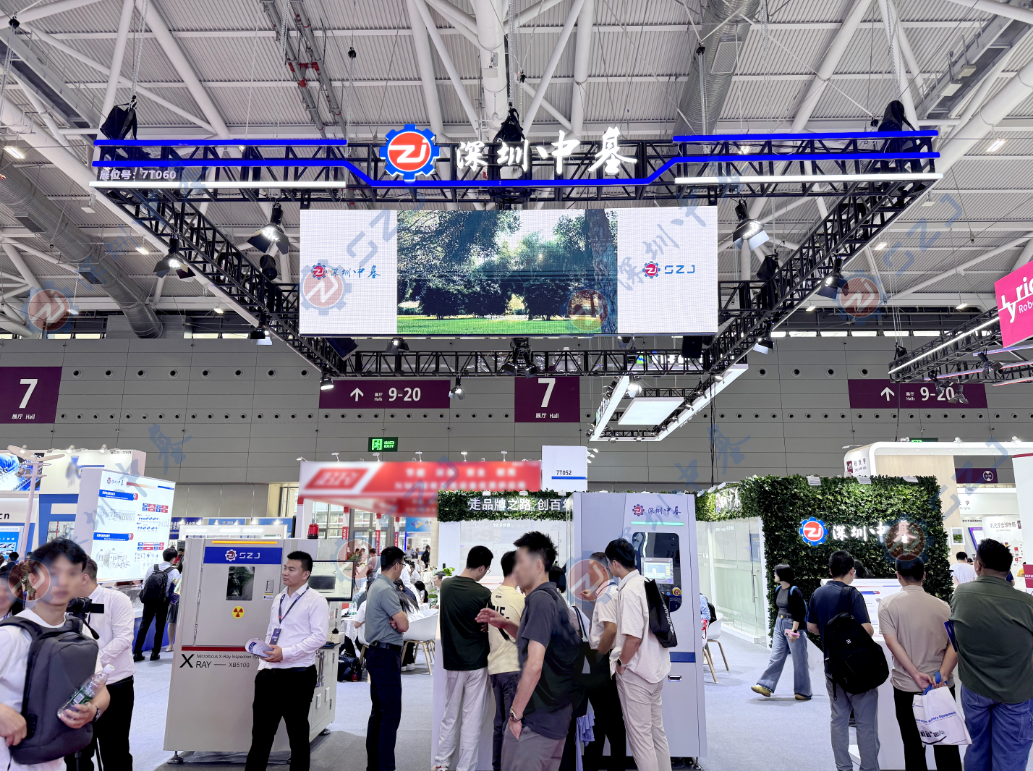

SZJ Returns to The Battery Show Europe, Showcasing Turnkey Lithium Battery Intelligent Manufacturing Solutions

From June 3 to 5, 2025, SZJ once again made its presence felt at The Battery Show Europe in Stuttgart, Germany, marking its second consecutive participation in this premier global event for the battery industry. As a leading company focused on intelligent manufacturing solutions for lithium battery equipment, SZJ is accelerating its