Incorporating state-of-the-art laser systems into our manufacturing processes allows us to accomplish precise cutting, welding, engraving, and measurement; introducing laser technology as a game-changer in industrial automation is something we are very excited about at SZJ Automation. With the extraordinary capabilities of laser technology, we can significantly enhance the quality and efficiency of our solutions in the rapidly evolving landscape of industrial automation companies.

Unmatched Precision in Cutting and Welding

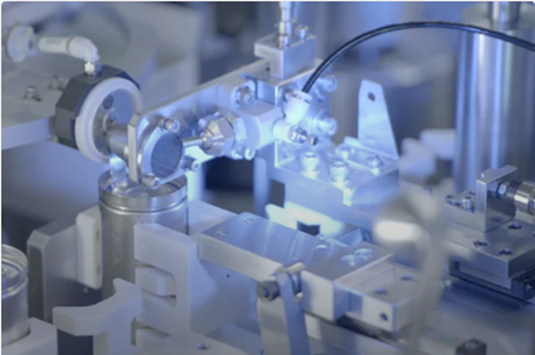

Laser technology utilizes a high-intensity, highly consistent beam produced by lasers which are meticulously focused and controlled through optical components. This allows us to accomplish precise cutting and welding of various materials. In the manufacturing sector, our laser cutting and welding technology is especially beneficial for applications like battery lug cutting, battery electrode cutting, liquid-filled hole welding, and battery module welding.

By implementing laser technology in these critical processes, we ensure that our equipment meets the stringent quality requirements of the battery manufacturing industry. The high precision achieved via laser cutting and welding not only reduces material wastage but also enhances production efficiency, a vital consideration for today’s competitive industrial automation companies.

Innovative Engraving and Marking Solutions

In addition to cutting and welding, our laser technology excels in engraving and marking applications. Utilizing this tech, we can achieve high-precision processing of material surfaces to create logos, patterns, and two-dimensional codes. This capability allows businesses to brand their products effectively while also providing essential information at a glance.

As industrial automation companies continue to adopt sophisticated manufacturing techniques, the need for precise engraving and marking solutions becomes increasingly important. Our advanced laser systems enable companies to maintain high-quality standards in their products, ensuring their market competitiveness.

Enhancing Efficiency and Quality in Battery Manufacturing

The integration of laser technology within our automation solutions promotes significant improvements in processing accuracy, production efficiency, and product quality. This is particularly relevant in the field of battery manufacturing, where we work closely with our partners to develop and implement tailored solutions that meet their specific needs.

By leveraging laser capabilities, we empower industrial automation companies to optimize their operations, leading to enhanced performance across workflows. As we continue to innovate and adapt, our focus remains on driving the growth of efficient and reliable manufacturing solutions that revolutionize the battery industry.

Conclusion

By harnessing the precise cutting, welding, engraving, and marking capabilities offered by lasers, we enhance production processes and improve overall product quality. As industrial automation companies look to elevate their manufacturing capabilities, we are excited to lead the way with advanced laser solutions designed for the future. Partner with us at SZJ Automation and experience the transformative power of laser technology in your operations, paving the way for excellence and innovation in the manufacturing landscape.