Innovative automation solutions are our specialty at SZJ Automation, and we’re committed to changing the battery production sector for the better. In order to guarantee unrivaled efficiency and quality in the production process, our team of specialists has decades of experience in developing and executing cutting-edge technology.

The Importance of Battery Production Line Optimization

In the rapidly evolving world of renewable energy, the demand for high-performance batteries has never been higher. As the global shift towards electric vehicles and clean energy storage continues to accelerate, the need for efficient and reliable battery production has become a critical priority. This is where SZJ Automation steps in, offering a comprehensive suite of solutions to optimize every aspect of the battery production line.

Enhancing Productivity with SZJ Automation’s Battery Production Line Solutions

One of the key areas where SZJ Automation excels is in the optimization of battery production lines. Our advanced solutions, such as the SZJ Battery Production Line, are designed to increase productivity and minimize downtime. By incorporating automated material handling systems, robotic assembly, and intelligent process control, we ensure seamless integration and streamlined workflows throughout the production process.

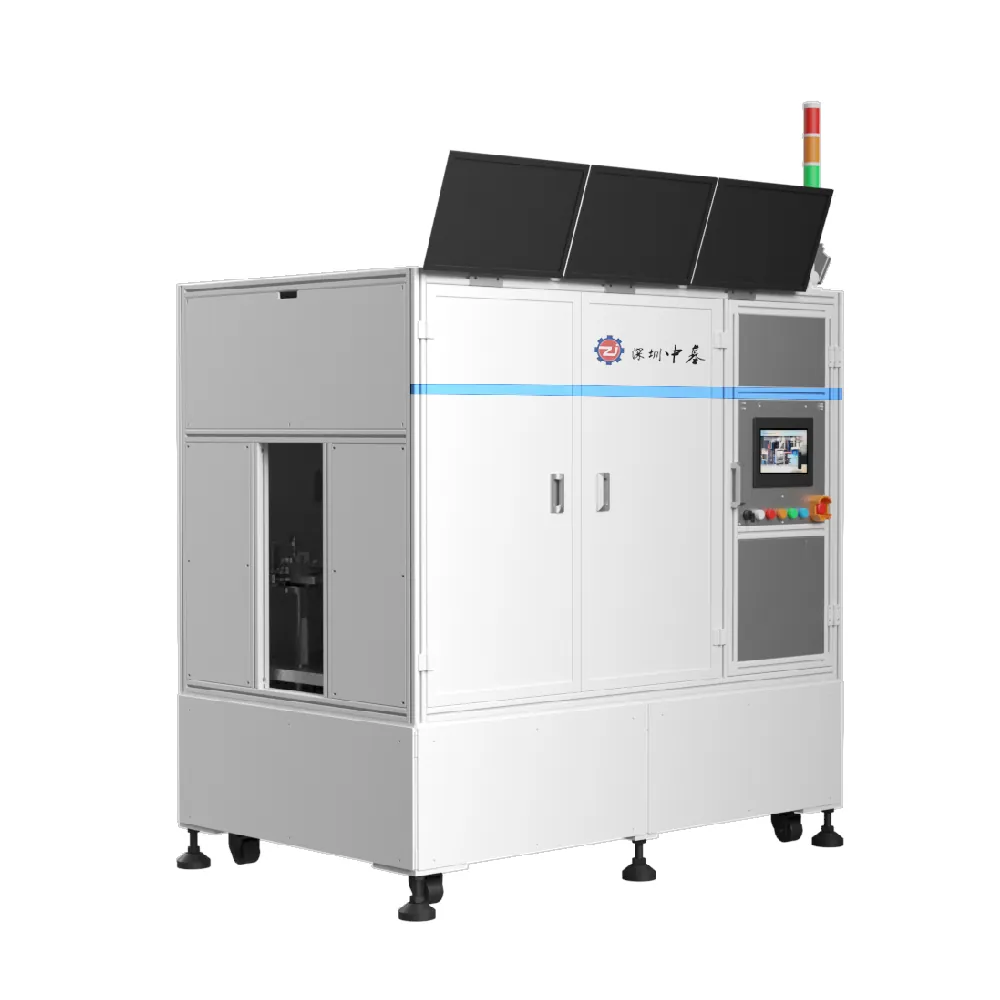

Improving Quality Assurance with SZJ Automation’s Appearance Inspection Machines

Ensuring the quality and consistency of battery cells is paramount in the production process. SZJ Automation’s state-of-the-art Appearance Inspection Machines, also known as Vision Inspection Systems, play a crucial role in this regard. These precision instruments enable automated and intelligent inspection of battery cell appearance and surface quality, allowing manufacturers to identify and address defects early on, ensuring the delivery of high-quality products to the market.

Reducing Operational Costs with SZJ Automation’s Battery Production Solutions

In addition to enhancing productivity and quality assurance, SZJ Automation’s battery production solutions also focus on reducing operational costs. By optimizing energy consumption, minimizing waste, and streamlining maintenance procedures, our solutions help manufacturers achieve significant cost savings, ultimately improving their bottom line.

Embracing Sustainability with SZJ Automation’s Battery Production Automation

At SZJ Automation, we recognize the importance of sustainability in the battery manufacturing industry. Our solutions are designed with a focus on reducing the environmental impact of battery production, incorporating energy-efficient technologies and promoting the use of renewable energy sources.

Conclusion

There is an urgent need for dependable and efficient production solutions due to the ever-increasing global demand for batteries. Leading the charge in this change is SZJ Automation, which provides an all-inclusive set of solutions for battery production lines that improve efficiency, reliability, and cost-effectiveness. Battery manufacturers may increase their efficiency, sustainability, and profitability by collaborating with SZJ Automation. This will put them in a better position to succeed in the dynamic energy market.