In the intricate process of cylindrical battery manufacturing, every step must be meticulously executed to ensure the reliability, efficiency, and performance of the final product. Among the crucial pieces of equipment utilized in this process, the winding machine stands out as a linchpin, playing a pivotal role in shaping the core structure of battery cells. Let’s delve into the essential functions and significance of winding machines in battery cell manufacturing, followed by an introduction to SZJ Automation‘s cutting-edge Winding Machine, engineered to optimize stability, precision, and longevity in cylindrical battery production.

Understanding the Role of Winding Machines in Battery Cell Manufacturing

- Core Structure Formation

Winding machines are responsible for creating the core structure of battery cells by precisely winding electrode materials, separator films, and other components into tightly wound coils. This process is essential for establishing the fundamental structure and integrity of the battery cell.

- Consistency and Uniformity

Winding machines ensure consistency and uniformity in the winding process, leading to uniform electrode thickness and density throughout the battery cell. This uniformity is critical for maintaining consistent performance and maximizing energy density across the entire battery pack.

- Stability and Precision

By adopting advanced control systems and precise mechanical design, winding machines ensure the stability and precision of the winding process. This stability and precision are essential for minimizing variations and defects, thereby improving the overall quality and service life of the battery.

Advantages of SZJ Automation’s Winding Machine

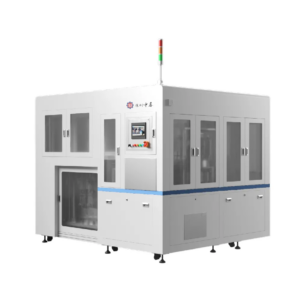

SZJ Automation’s Winding Machine represents the epitome of precision engineering and reliability in cylindrical battery manufacturing. Here’s why it stands out:

– Advanced Control System Our Winding Machine adopts an advanced control system, ensuring precise control over winding parameters such as tension, speed, and direction. This level of control enables consistent and uniform winding, minimizing variations and defects.

– Precise Mechanical Design Engineered with precision mechanical design, our Winding Machine ensures the stability and accuracy of the winding process. Each component is meticulously crafted to withstand the rigors of high-speed winding operations while maintaining optimal performance and reliability.

- Enhanced Stability and Precision With its advanced control system and precise mechanical design, our Winding Machine delivers unmatched stability and precision in the winding process, ensuring uniform electrode thickness and density for superior battery performance.

- Streamlined Production SZJ Automation’s Winding Machine streamlines the production process, enabling manufacturers to achieve higher throughput rates and meet increasing demand without compromising quality or performance.

Conclusion

In conclusion, winding machines play a crucial role in shaping the core structure of cylindrical batteries, ensuring consistency, uniformity, stability, and precision in the winding process. With SZJ Automation’s advanced Winding Machine, manufacturers can elevate their production capabilities, optimize battery performance, and unlock new possibilities for innovation in the dynamic world of battery technology.