The Development of Battery Manufacturing Equipment in East Asia

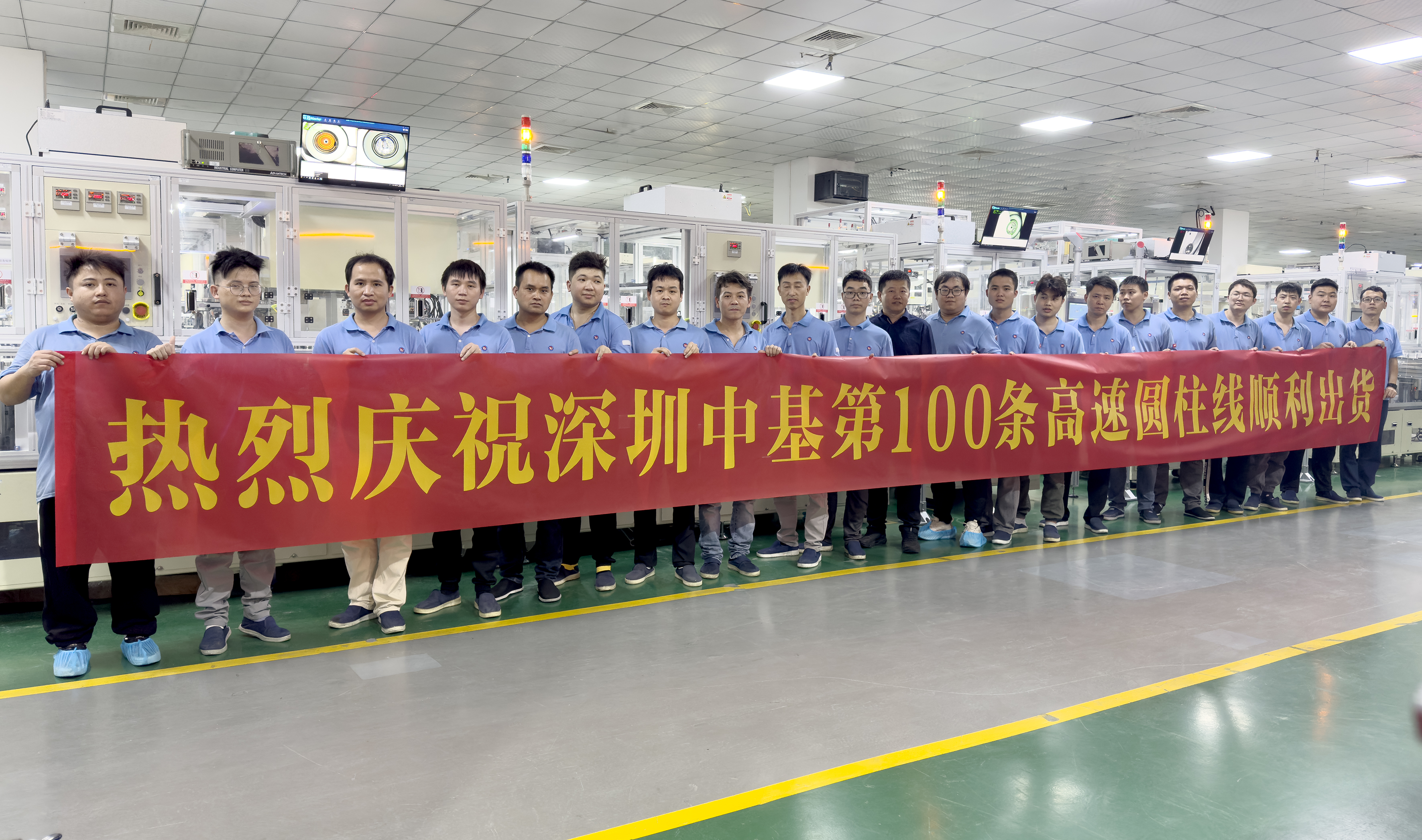

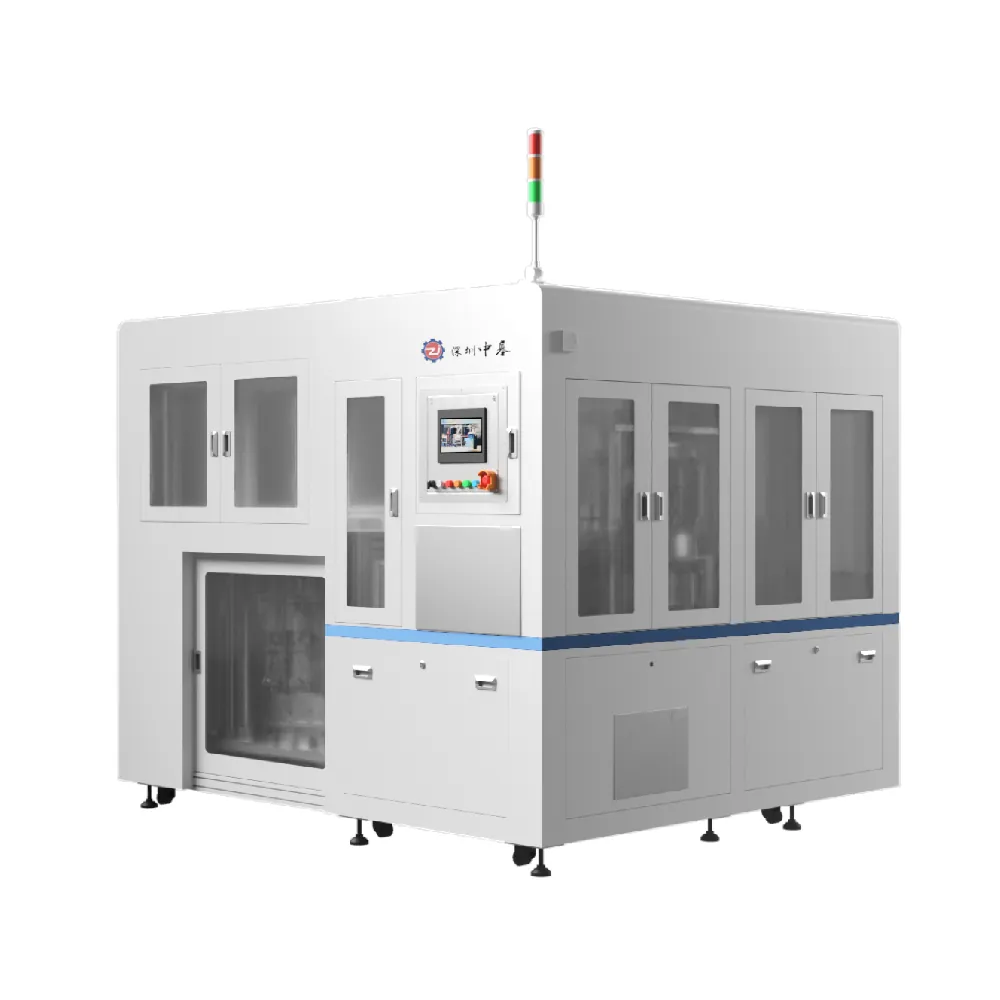

East Asian countries like South Korea, Japan, and China are leading the charge in advancing battery manufacturing equipment. Their innovations have shaped the global energy landscape, providing the tools needed to produce efficient, reliable, and high-performance batteries. These nations have not only kept up with the growing demand for sustainable energy solutions but also set the benchmark for modern battery technologies. This article explores how East Asia has risen to dominate the industry. From its early contributions to cutting-edge advancements, we’ll look at how these countries have maintained their leadership. (Copryright Photo from: https://www.freepik.com/free-photo/top-view-recycled-batteries_27595699.htm) The Origins of Battery Manufacturing in East Asia Countries The rise of battery manufacturing in East Asia began decades ago, driven by strategic investments and long-term planning. Japan recognized the potential of this industry early on, laying a solid foundation for its global leadership today. In 1985, Japanese scientist Akira Yoshino developed the first lithium-ion battery prototype. Then, in 1991, Sony was commercialized, and in 1994, Panasonic produced the first scale model in the battery manufacturing industry. This innovation laid the groundwork for modern rechargeable battery systems and significantly enhanced the performance and efficiency of batteries used in various applications[1]. Advancing Technologies: East Asia’s Rise in Battery Innovation East Asia has become a leader in manufacturing lithium-ion batteries by consistently pushing the boundaries of technology. The region’s focus on innovation has transformed battery production into a cornerstone of global progress. South Korea South Korea is home to leading battery manufacturers such as LG Energy Solution and Samsung SDI. These companies have developed high-capacity LIBs, focusing on improving energy density, charging speed, and lifespan. South Korean firms are also exploring alternative chemistries, including lithium iron phosphate (LFP) batteries, which offer cost advantages and enhanced safety profiles. LG Energy Solution, for example, is in discussions with Chinese suppliers