Scaling up battery production using conventional battery assembly methods has become increasingly challenging due to the surging demand for battery-powered products. It would be hard to meet the precise cell alignment, consistent quality and production levels, on-time completion, and rising competition are some of the biggest challenges. Additionally, factors such as the necessity to invest in logistic infrastructure and the challenge of meeting stringent environmental and safety regulations add another layer of complexity to boosting battery manufacturing and assembly methods.

These challenges highlight the need for upgrading better battery assembly solutions to improve efficiency and drive industry progress in the future. And this is where smart manufacturing comes into play.

What is Smart Manufacturing?

Smart manufacturing in battery assembly involves integrating advanced automated technologies to optimize production, ensure quality control, and enhance safety. The robotic system employed in the smart manufacturing techniques can significantly reduce downtime, minimize errors, and offer quality control on the battery pack assembly line.

What are the Principles of Smart Manufacturing in Battery Assembly?

Understanding the principles of smart manufacturing will help you understand why more and more businesses are transitioning to this next-generation manufacturing technique.

Smart manufacturing is a sophisticated system that accelerates the fabrication and assembly process by employing computing automation at every step. It creates a digitally connected manufacturing environment where the production processes are supervised using data analytics. Capable of making autonomous decisions, the smart manufacturing system has revolutionized both the manufacturing sector and the economy.

Talking specifically, here is a rapid overview of all the foundational principles supporting this groundbreaking approach.

- The smart production process is based on a network of communication involving battery assembly machines, devices, sensors, and people. This connectivity facilitates live monitoring and management of the battery manufacturing process, grasping a more comprehensive status during the manufacturing compared with conventional assembling line.

- Computing automation is at the core of smart manufacturing. An automated battery production unit can make informed decisions from computers or algorithms with minimum chances of errors, then act swiftly based on the setting without adjustment, differentiating from the manual or other conventional operations.

- Digitalization is another essential rule of smart assembly techniques. Digitalization refers to the process of converting information to digital format. In smart manufacturing, it means utilizing digital technologies to digitize physical assets and processes. It enables efficient analysis and optimization.

- The smart manufacturing process also revolves around the idea of sustainability. It optimizes resource utilization and minimizes waste. It leads to a substantial decrease in environmental footprint, achieving sustainable goals for a brighter future.

What are the Key Components of Smart Manufacturing in Battery Assembly?

An advanced battery assembly manufacturing facility integrates various cutting-edge technologies to enable intelligent, connected, and automated processes, optimizing manufacturing operations.

However, implementing a smart manufacturing assembly line requires the combination of several key components. The most essential components for a smart manufacturing battery assembly factory include the following:

1. Internet of Things (IoT)

IoT, or the Internet of Things, is considered to be the backbone of a smart factory. It is a network of interconnected devices, machines, and sensors that can exchange data with each other over the Internet. The sensors and devices facilitate real-time monitoring and optimization of manufacturing processes. They provide valuable insights into machine performance, energy consumption, and production quality. This makes IoT a vital component of a battery manufacturing smart factory.

Sensors are strategically embedded throughout the battery assembly automation line to monitor critical parameters such as temperature, humidity, and machine performance. This enables early detection of abnormalities, facilitating proactive maintenance measures. The system utilizes algorithms to analyze data and predict equipment failures, thereby minimizing downtime and decreasing maintenance expenses. IoT-enabled devices also track components, ensuring the use of high-quality materials and immediate corrective actions for defects.

IoT sensors can also monitor energy consumption throughout the assembly line, identifying opportunities for optimization. Moreover, the sensors and devices also enable remote monitoring and control of the assembly line, allowing managers to oversee operations from afar. This enhances flexibility, responsiveness, and agility in managing production processes.

2. Cloud Computing

Cloud computing provides the essential infrastructure required to manage the extensive data generated within a smart factory. It offers scalable and flexible storage solutions, empowering the factory to expand and adjust as necessary. Moreover, it facilitates instant access to data from any location, simplifying remote monitoring and control processes.

In battery assembly, cloud computing provides secure storage solutions for extensive data collected from sensors, machines, and production activities. This data encompasses details on quality control, equipment performance, and energy usage, facilitating analysis for informed decision-making. Utilizing analytic tools, a cloud-based battery assembly unit can analyze real-time sensor data to predict equipment failures, optimize maintenance schedules, and ultimately minimize downtime and reduce maintenance expenses.

Additionally, cloud computing offers scalability and flexibility, allowing battery manufacturers to adjust their computing resources according to fluctuating demands. Cloud platforms seamlessly integrate with IoT devices and automation systems used in battery assembly, enabling immediate data exchange and streamlining automation, optimization, and decision-making in manufacturing operations.

3. Automated Machines

Automation plays an essential role in smart manufacturing. They enable the automation of repetitive tasks, which enhances productivity and elevates quality standards. Moreover, it can operate round the clock, minimizing downtime and boosting output. Sophisticated automation designed with computing capabilities brings consistency and precision to assembly line automation.

SZJ Automation: A Perfect Automated Battery Assembly Solution

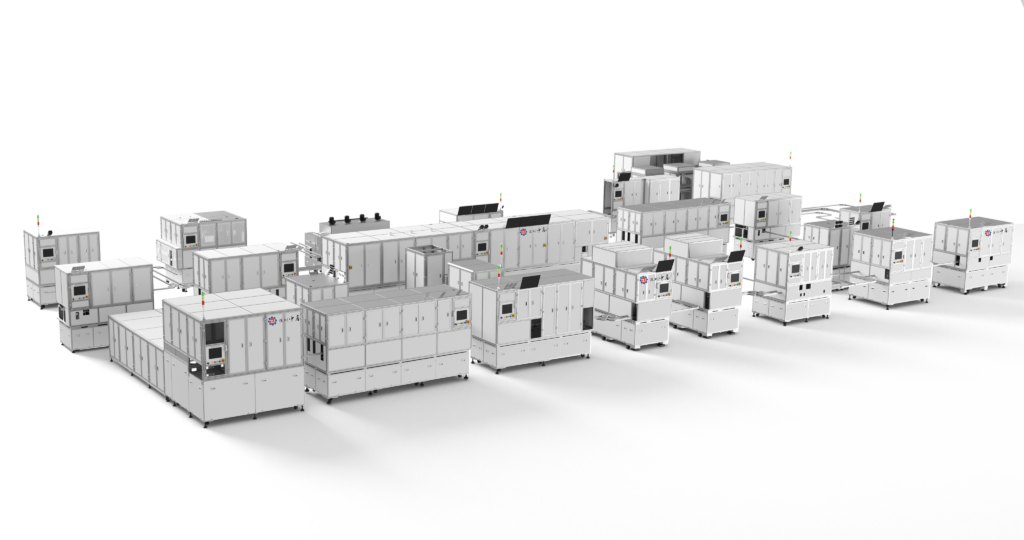

In short, you cannot beat the competition without adapting to smart manufacturing. And we, SZJ Automation, specialize in automated machines for assembling cells, delivering the best production during the process of smart manufacturing.

Our highly skilled R&D team has engineered several turnkey solutions in battery manufacturing to ensure efficient and stable production from raw materials to finished batteries.

Like our Pouch Cell Production Line Turnkey Solution, this suite of assembly line automation includes an inspection machine that diligently monitors production completion, a battery-filling machine that enhances efficiency and stability, a grading and hot-pressing machine that ensures precision, and much more. As a result, our battery assembly turnkey solution boasts a steady production efficiency ranging from 6 to 20PPM for prismatic batteries. With our proprietary continuous laser welding technology, productivity soars by a staggering 3~5 times compared to traditional methods for prismatic and blade cell batteries. It’s a paradigm shift in efficiency, precision, and quality control, setting a new standard in the industry.

Conclusion

For battery manufacturers, upgrading to smart manufacturing can make the factory more efficient and quantified. SZJ Automation is a leading manufacturer of smart equipment technology. We offer user-friendly and compact cell manufacturing machines that effortlessly support large-scale production without compromising sustainability or quality.

With over 20 years of experience in innovative technology, quality control, and professionalism, we can modernize your outdated manufacturing assembly line into a smart workplace. If you are interested, please visit our SZJ’s official website to learn more information about our automated assembly lines, or contact us at any time.