In industrial battery supply, there is a complete chain to ensure the perfect production of high-quality batteries. Factors from raw material extraction and refinement to the finished battery pack are emphasized. A crucial first phase of this chain is the preparation of battery pack material. It involves thorough pre-processing, synthesis, and modifications to transform raw materials into optimized compounds tailored for optimal battery performance.

Industrial Battery Supply Step 1: Materials Selection

For battery supply, you need to manufacture batteries. Material selection is the first step to start battery manufacturing. Lithium, cobalt, nickel, manganese, and graphite are top choices that are preferred in industrial battery supply for several reasons. Here’s a table about that:[1][2]

Material | Where to Find? | What Advantages? |

Lithium | Often found in brine deposits or hard rock in its natural lithium inorganic salt-based form | Offers high energy density, making batteries lighter and longer-lasting |

Cobalt | Primarily extracted from ore deposits in its natural metallic cobalt form | Enhances performance and safety by withstanding high temperatures |

Nickel | Comes from laterite ores in their natural metallic nickel form | Contributes to overall energy capacity and longevity |

Manganese | Derives from manganese ore in its natural manganese oxide mineral form | Improves safety by stabilizing the cathode |

Graphite | Obtained from graphite mines in its natural graphitic carbon form | Serves as an anode thanks to its excellent conductivity and ability to intercalate lithium ions efficiently |

Industrial Battery Supply Step 2: Raw Material Pre-Processing

In the upstream industrial battery supply, crucial pre-processing is required from the raw materials stage all the way to battery integration. Phases may vary depending on the battery pack material. Generally, these include:

- Chemical Purification: Refining removes impurities through processes like lithium extraction from brine undergoes evaporation and further chemical treatments[3].

- Physical Processing: Cobalt and nickel ores undergo grinding to break down into finer particles for easier handling.

- Concentration: Concentrating lithium in brine boosts yield through techniques like solar evaporation ponds.

- Separation: Leaching separates valuable metals from waste using chemical solvents for nickel and cobalt recovery.

- Drying/Calcination: Drying and high-heat processes convert manganese and lithium compounds into purer forms.

Chemical purification is the most crucial phase in industrial battery supply due to its impact on overall battery performance. It’s essential because impurities significantly harm battery efficiency, lifespan, and safety. For example, trace metals in lithium can cause dendrite formation, leading to short circuits.

Moreover, high-quality materials optimize electrochemical reactions, boosting energy density, cycle life, and overall reliability. This critical pre-processing stage establishes a foundation for manufacturing top-performing lithium vehicle battery packs so that material quality standards are met.

Industrial Battery Supply Step 3: Synthesis and Chemical Modification

The next step upstream of industrial battery supply is synthesis and chemical modification. They enhance the electrical properties of battery materials. Through precise reactions, raw battery pack material types are transformed into specialized compounds.

Modifications impact electrical behavior by optimizing crystal structures and compositions. Synthesizing lithium cobalt oxide from lithium and cobalt sources generates a stable crystal structure suitable for cathodes. Likewise, treating graphite enhances the introduction of lithium ions into its anode structure. Both modified materials facilitate swift lithium-ion diffusion. They strengthen energy density and cycle life.[4]

Summary of Upstream of Industrial Battery Supply

The upstream of industrial battery supply means the preparation of battery assembly. It involves multiple crucial stages, including a selection of optimal compounds, purification, and modification through synthesis and reaction to customize properties. This establishes the foundation for the next pivotal phase – battery manufacturing.

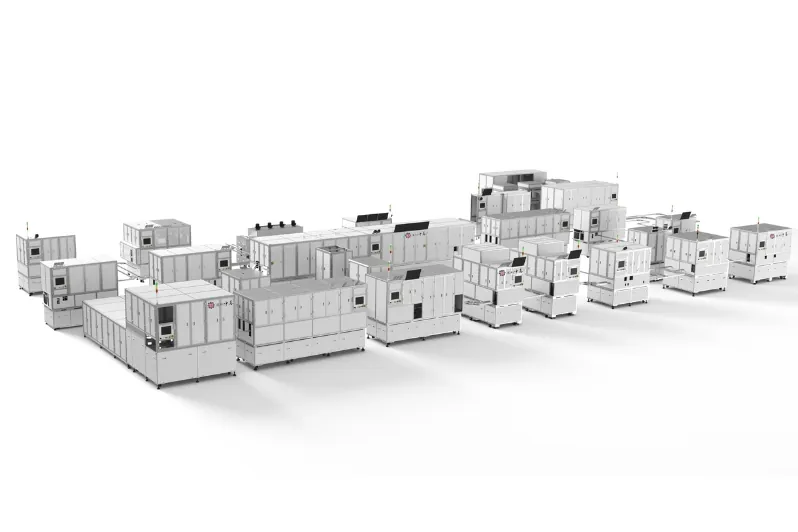

At this stage, the prepared materials undergo specialized manufacturing processes to assemble into finished energy storage units. And our SZJ Automation’s battery manufacturing turnkey solution could deliver a complete, efficient and reliable production for your manufacturing needs. Here, we are taking our Pouch Cell Turnkey Solution as an example.

This solution we designed is aimed at empowering the lithium battery sector to improve the entire industrial battery supply. Our solution boasts an impressive production rate of 10-24 PPM, ensuring nearly perfect product quality with a 99% qualification rate and an exceptional 98% equipment utility rate. Here’re the major battery manufacturing equipment applied in this turnkey solution:

- Appearance Inspection Machine

- Electrode Filling Machine

- Degassing Machine

- Grading Machine

- OCV Testing System

- Trimming, Folding, and Hot-Pressing Machine

Conclusion

To ensure the efficiency and completeness of industrial battery supply, every link needs to be perceived carefully. In the upstream, it is significant for the understanding of battery materials selection, pre-processing and synthesis, and chemical modification so as to ensure better battery manufacturing.

At SZJ Automation, we are an expert in providing professional and reliable battery manufacturing solutions like our Pouch Cell Production Line Turnkey Solution to keep industrial battery supply productive and intelligent. With 20+ years of experience in battery engineering and production, we can provide customers with reliable solutions to meet rising global energy demands. For more information on other solutions and services, browse our SZJ Automation’s official website to learn more and contact us!

References

- Available at: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8390110/

- Available at: https://lohum.com/media/blog/an-overview-of-top-10-minerals-used-as-battery-raw-material/

- Available at: https://www.palamaticprocess.com/blog/the-process-of-purifying-ores-for-battery-manufacturing

- Available at: https://link.springer.com/chapter/10.1007/978-0-387-92675-9_3