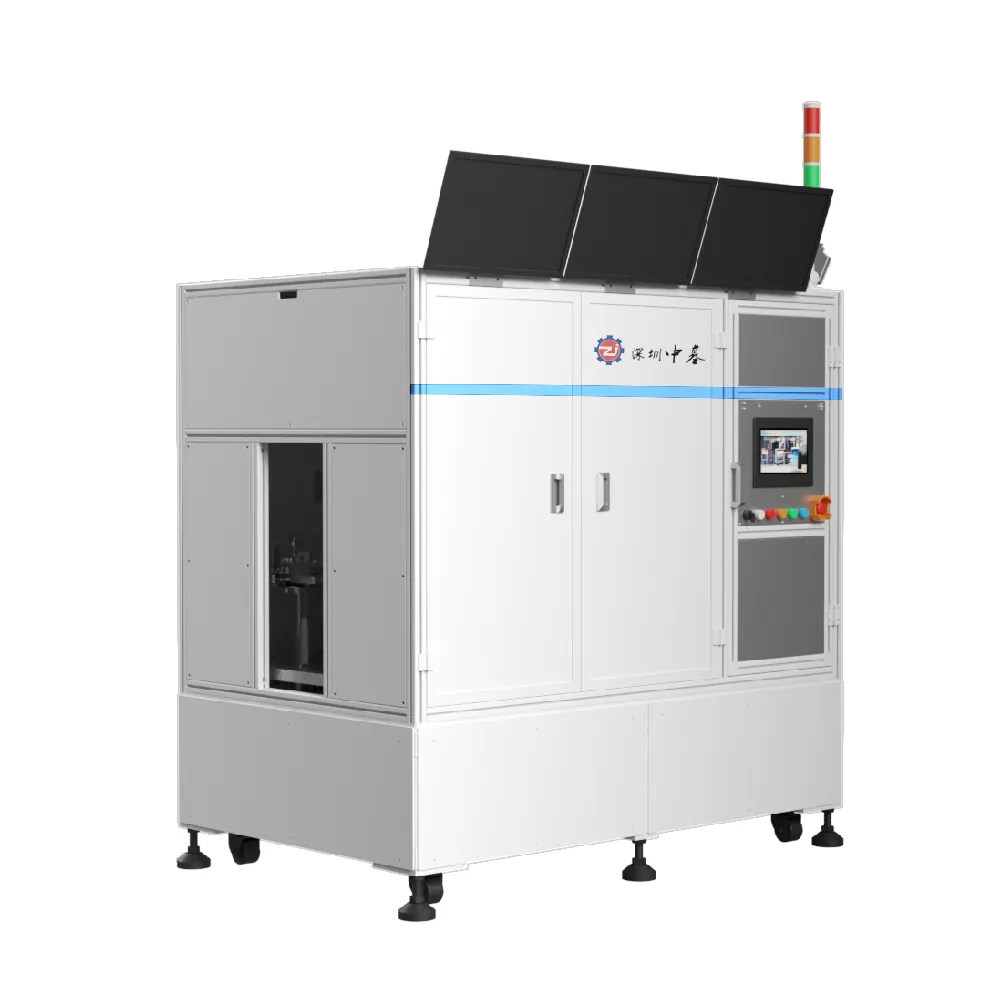

Embark on a journey of precision and excellence in quality control with SZJ Automation‘s advanced Appearance Inspection Machines. Equipped with high-resolution cameras, specialized lighting systems, and state-of-the-art image processing capabilities, our machines redefine the standards of appearance inspection in automated production lines. Explore how SZJ Automation’s innovative technology ensures meticulous assessment of product surfaces, identification of defects, and efficient sorting processes, setting new benchmarks for quality assurance in manufacturing.

High-Resolution Imaging: Enhancing Inspection Precision

At the core of SZJ Automation’s Appearance Inspection Machines lies the power of high-resolution cameras, enabling detailed imaging of product surfaces with unparalleled clarity. These cameras capture intricate details and surface features, facilitating thorough inspection processes in automated production lines. By utilizing high-resolution imaging technology, manufacturers can achieve precision in defect detection and quality assessment, ensuring that every product meets the highest standards of quality and performance.

Illuminating Excellence: Specialized Lighting Systems

Lighting plays a crucial role in highlighting surface features and defects during inspection processes, and SZJ Automation’s Cell Inspection Machines feature specialized illumination systems for optimal visibility. Proper lighting enhances the accuracy of defect detection, enabling manufacturers to identify imperfections with precision on automated production lines. With our advanced lighting solutions, SZJ Automation ensures that no detail goes unnoticed, guaranteeing thorough and effective inspection results for enhanced quality control.

Advanced Image Processing: Analyzing Defects with Precision

The heart of SZJ Automation’s Appearance Inspection Machines lies in their sophisticated image processing system, which employs advanced algorithms to analyze captured images and identify visual defects or irregularities. By leveraging cutting-edge image processing technology, our machines can detect even the subtlest imperfections with accuracy and efficiency. Manufacturers can rely on SZJ’s image processing capabilities to streamline defect identification processes and maintain the highest standards of quality in automated production lines.

Defect Classification and Sorting: Enhancing Efficiency in Quality Control

Once defects are detected, SZJ Automation’s auto appearance inspectors excel in classifying them based on predefined criteria such as size, shape, location, and severity. This automated defect classification and sorting process streamlines quality control operations on production lines, enabling manufacturers to efficiently address and resolve issues. With SZJ’s defect classification and sorting capabilities, businesses can optimize their quality control workflows, ensuring consistent product quality and performance in automated production environments.

Conclusion:

In conclusion, SZJ Automation’s Appearance Inspection Machines represent a paradigm shift in quality control for automated production lines, offering unmatched precision, efficiency, and reliability in defect detection and classification. With high-resolution cameras, specialized lighting systems, advanced image processing technology, and automated defect sorting capabilities, our machines empower manufacturers to uphold the highest standards of quality assurance in manufacturing processes. When it comes to automated assembly lines, SZJ Automation is your best bet for appearance inspections, helping you reach new heights of efficiency and quality.