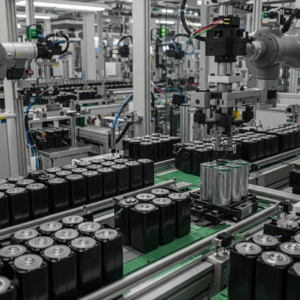

In the ever-evolving landscape of manufacturing, efficiency, precision, and seamless integration are paramount. At SZJ Automation, we understand the intricacies of modern production processes, which is why we’ve developed cutting-edge production cell technology that redefines efficiency and control from design to testing. Let’s delve into how our battery automated manufacturing line technology sets new standards in digital management, automation, and control.

Full Manufacturing Cycle Digital Management

- End-to-End Automation and Control

Our cell automated manufacturing line technology encompasses the entire manufacturing cycle, from design and simulation to testing and analysis. Through seamless automation and control, every step of the process is managed digitally, ensuring precision, consistency, and efficiency from start to finish.

- Visualized Management Mode

We believe in making the manufacturing process visually accessible and easy to manage. Our digital management mode provides real-time visualization of production processes, enabling operators to monitor operations, identify potential bottlenecks, and make data-driven decisions for continuous improvement.

HMl Standardization for Enhanced Efficiency

- Unified Functional Design

SZJ Automation adopts HMl (Human Machine Language) with a unified functional design, ensuring consistency and clarity across all aspects of the cell automated manufacturing line interface. This standardized approach simplifies operation and reduces the learning curve for operators, enhancing overall efficiency.

- Customization and Standardization

While adhering to HMl standards, our production cell technology offers flexibility for customization to meet the unique needs of each customer. Different style options are available to accommodate individual preferences while maintaining design standardization. This eliminates the need for repeated programming, saving valuable time and resources.

Advantages of SZJ Automation’s Production Cell Technology

- Efficiency By streamlining the manufacturing process and eliminating manual interventions, our production cell technology improves operational efficiency, reducing cycle times and increasing throughput.

- Precision With digital management and automation, our technology ensures precision and consistency in every aspect of production, from design to testing, resulting in high-quality outputs.

- Standardization HMl standardization not only simplifies operation but also promotes consistency and reliability, enabling smoother integration into existing manufacturing environments.

- Customization Despite standardized interfaces, our production cell technology offers flexibility for customization, allowing us to tailor solutions to the specific requirements of each client.

Conclusion

In conclusion, SZJ Automation’s cell automated manufacturing line technology represents a leap forward in manufacturing excellence. By combining full manufacturing cycle digital management with HMl standardization, we empower our clients to achieve greater efficiency, precision, and control in their production processes. Experience the future of manufacturing with SZJ Automation and unlock new possibilities for your business.