Cell Insertion Machine

Dedicated for best quality innovations

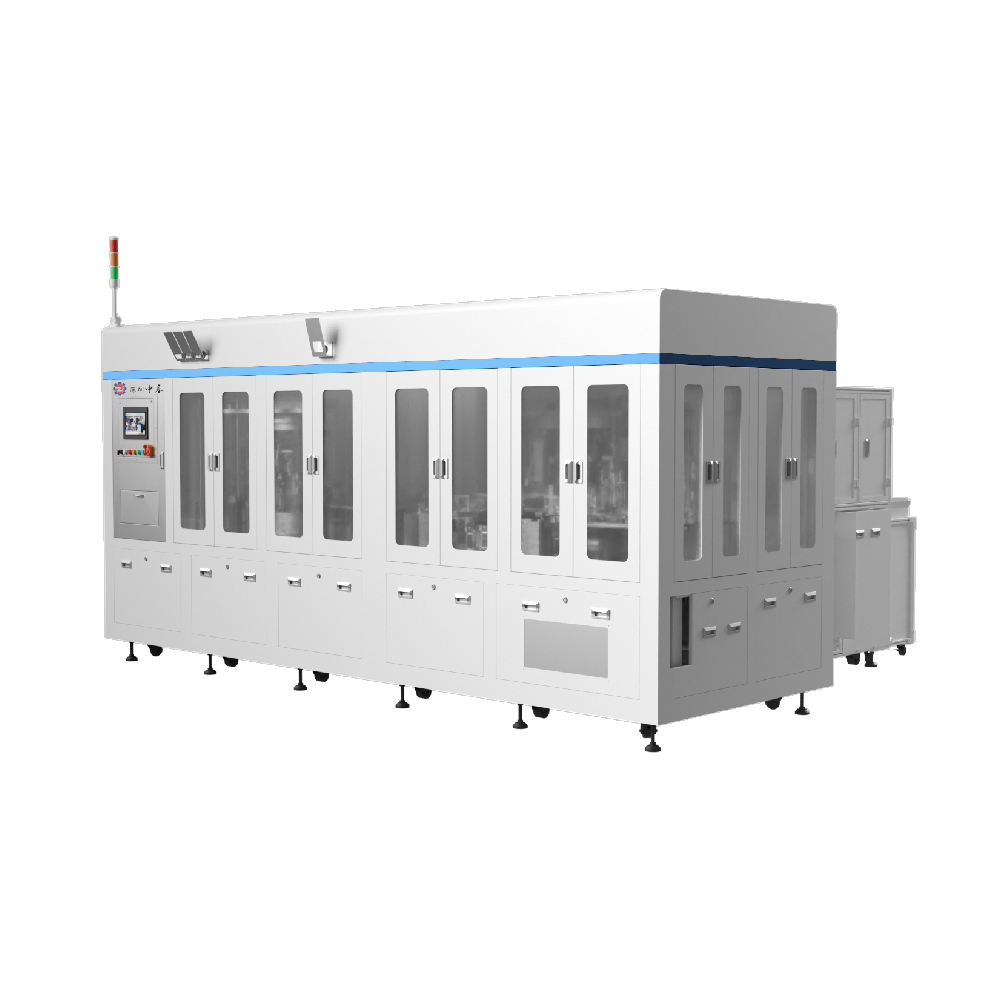

Cell Insertion Machine

The equipment is designed as a turret-type cam transmission mechanism, utilizing high-precision gauging for the outer diameter of the rolled core, dual optical fiber sensors for ear correction and positioning, magnetic adsorption shell transportation, and real-time feedback and correction using pressure sensors. This technology for the lossless insertion of cylindrical battery cells into the shell completes the process of rolling core insertion into the shell with high quality and efficiency.

Equipment Parameters

| False judgment rate of core outer diameter detection | ≤ 0.1% |

| Leakage detection | 0% |

| B/I Insertion of the relative position accuracy of the special bracket cup | within ± 0.1mm |

| B/I blanking mold blanking accuracy | ± 0.1mm or less |

| B/I punching mold service life | 15 million times |

Related Products

-

Laser Sealing Machine

The equipment is used for laser sealing welding between the top cover and the shell of a square aluminum shell battery to achieve a seal between the top cover and the shell. -

Inserting & Pre-welding Machine

The equipment is used for the automatic assembly of cells and shells for square aluminum-cased batteries, as well as post-assembly press-fitting, step gap detection and laser pre-spot welding fixation. -

Mylar Wrapping Machine

The equipment is used for the assembly and fusion welding of Mylar and cells of square aluminum-cased batteries on the top cover bracket, which protects the cells. -

Ultrasonic Welding Machine

The equipment is used for ultrasonic welding of the adapter piece of the square aluminum shell battery and the battery cell after assembly, through high-frequency vibration, the adapter piece and the battery cell lugs will be fused tightly, so as to achieve the purpose of current conduction.